Using a copper pro distiller is a popular choice among home distillers for its superior heat conduction and ability to remove sulfur compounds during the distillation process. If you're looking to distill alcohol at home, understanding how to properly use an alcohol still is crucial for safety, quality, and efficiency. In this article, we'll guide you through the essential steps to using a copper pro distiller for alcohol distillation, ensuring you achieve the best possible results.

What is a Copper Pro Distiller?

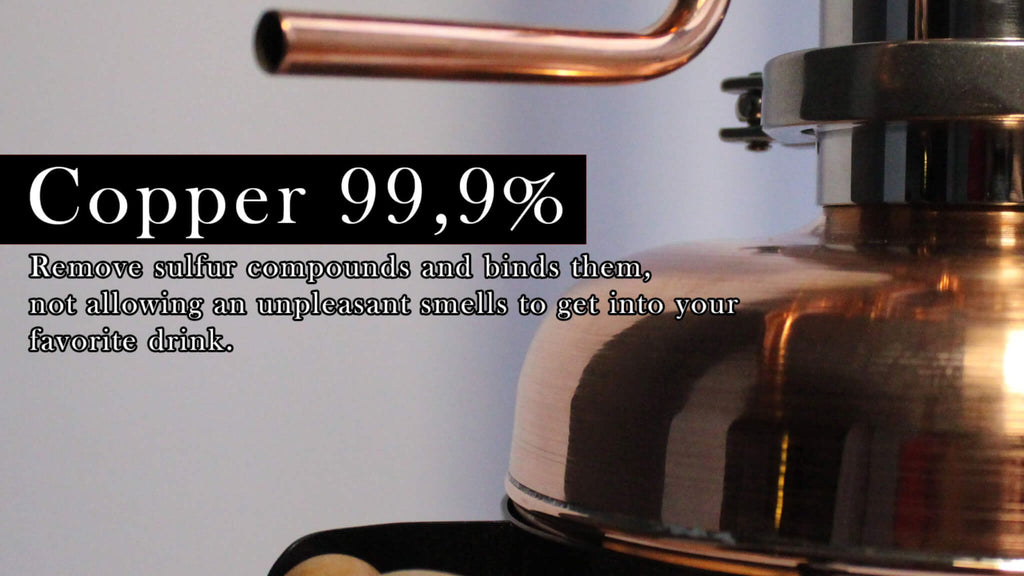

A copper pro distiller is a type of alcohol still made primarily from copper, a material highly valued in the distillation process. Copper's excellent thermal conductivity allows for even heating and helps in the removal of unwanted sulfur compounds, which can improve the taste and quality of the distilled alcohol. Copper stills are widely used for producing a variety of spirits, including whiskey, vodka, gin, and rum.

Preparing Your Copper Pro Distiller for Use

Before you begin the distillation process, it's important to prepare your copper pro distiller properly. Here's how to get started:

1. Clean the Distiller

Cleaning your alcohol still before use is crucial. Start by rinsing all components of the copper pro distiller with warm water to remove any dust or debris. For a more thorough clean, use a solution of water and vinegar or a specialized distiller cleaner. This step ensures that any residues from previous distillations or manufacturing are removed, which can affect the taste and quality of your alcohol.

2. Assemble the Distiller

Follow the manufacturer’s instructions to assemble your copper pro distiller. Ensure all seals are properly tightened and that there are no leaks. A leak-proof seal is essential to prevent alcohol vapors from escaping, which could reduce your yield and pose a fire hazard.

3. Prepare the Mash

The mash is the fermented mixture that will be distilled to produce alcohol. Depending on the type of spirit you want to make, your mash ingredients will vary. For example, whiskey uses a grain mash, while rum uses molasses. Once your mash is prepared and fermented, it is ready for distillation.

Distilling Alcohol with a Copper Pro Distiller

Once your distiller is prepared and your mash is ready, you can begin the distillation process. Here’s a step-by-step guide:

1. Fill the Boiler

Pour the fermented mash into the boiler of the copper pro distiller. Be careful not to overfill the boiler; leaving some space allows for expansion and prevents boiling over. The ideal fill level is usually between half and three-quarters full.

2. Heat the Boiler

Once the boiler is filled, heat it slowly. Using a heat source like a propane burner or an electric hot plate, gradually increase the temperature to bring the mash to a boil. The goal is to heat the mash to the point where the alcohol evaporates but the water does not, which typically occurs at around 173°F (78°C).

3. Monitor the Distillation Process

As the mash heats up, alcohol vapor will rise into the distiller's column and condense into liquid in the condenser. It’s important to monitor the temperature closely. Too high a temperature can cause impurities to distill, while too low a temperature can reduce alcohol yield.

4. Collect the Distillate

The first portion of distillate, known as the "foreshots," contains methanol and other harmful compounds and should be discarded. Continue to collect the distillate, monitoring its proof and temperature to ensure you are collecting the "hearts," which is the purest part of the distillation. The "tails," or the last portion of the distillate, may contain unwanted flavors and can be set aside for redistillation.

Post-Distillation Procedures

After distilling alcohol using a copper pro distiller, there are a few essential steps to finalize the process and maintain your equipment:

1. Dilute and Bottle Your Alcohol

The alcohol collected will likely be at a high proof, often over 100 proof (50% ABV). For most spirits, this is too strong for drinking, so you will need to dilute it with water to the desired proof, typically between 80 and 100 proof (40-50% ABV). Use distilled water to avoid any impurities. Once diluted, bottle the alcohol in sterilized containers.

2. Clean the Distiller Thoroughly

After each use, clean your alcohol still thoroughly. Disassemble the copper pro distiller and rinse all components with warm water. A thorough cleaning prevents residue buildup, which can affect the taste of future batches. For stubborn residues, a mixture of water and vinegar can be used.

Tips for Using a Copper Pro Distiller Safely

While distilling alcohol can be a rewarding hobby, it’s important to prioritize safety:

- Work in a well-ventilated area: Alcohol vapors are flammable and can be dangerous if not handled properly.

- Avoid open flames: Since alcohol vapors can ignite, it's safer to use electric heating sources.

- Monitor temperature closely: Use a reliable thermometer to keep track of the temperature throughout the distillation process.

Conclusion

Using a copper pro distiller for alcohol distillation is a process that requires attention to detail and adherence to safety protocols. By following the steps outlined in this guide, you can efficiently produce high-quality spirits at home. Remember to clean your equipment thoroughly, monitor temperatures carefully, and always prioritize safety when operating an alcohol still. With practice and patience, you'll be able to refine your distilling techniques and enjoy the fruits of your labor.